The high selling price of CPO, thus providing a large profit so that it can cover production costs, certainly does not last forever. The success of FFB production in palm oil plantations is one of the keys to the success of CPO production. The success of FFB production is related to the success of the plantation and the highest cost component in palm oil plantations is the cost of fertilizer. The high need for palm oil fertilizer for each palm tree reaches around 10 kg annually and this fertilizer is non-subsidized. Fertilizer as one of the components in the CPO production cost chain is easy to buy if the price of CPO is high or there is a big profit. But solely relying on the current high CPO price for the palm oil business operations is certainly a mistake.

And the fact is that in 2019 the price of CPO has fallen and the palm oil industry has suffered losses or almost no profit at all. The fact is that when there is a decline in CPO prices it also raises concerns for Indonesia because the palm oil industry has many strategic roles both economically, socially and environmentally. It was noted that CPO prices have continued to decline every month since 2018 compared to prices of CPO at 2017. This downward trend has touched world CPO prices since 2015. The CPO price was recorded at $448/ton in November 2018. Even though the world CPO price in 2018 2016 and 2017 averaged over $700/ton. On average, CPO prices decreased by 15-16 percent compared to 2017. Exports of CPO to Indonesian traditional markets, namely the European Union and India in 2018 also decreased compared to 2017.

And it's not impossible that this will happen again. Such as past experience in the form of accusations of an issue from the European Union Parliament which aims to prevent palm oil from Indonesia from dominating the European market, so that CPO exports decrease, a trade war that can occur at any time. While the excuses used are about deforestation, child labor practices and utilizing customary forests. This certainly should be a valuable lesson. The only way PTPN holding can work around this is by downstreaming CPO products (CPO derivatives), namely by creating an oleochemical industry. If the CPO price drops, the majority of CPO will be brought to downstream products. If the downstream product margins are not good, the majority is just CPO. Production flexibility is a strategy that makes the palm oil industry "immune" to crises. The majority of their products, both CPO and its derivatives, are for export. But downstreaming the palm oil industry is also not an easy and cheap thing that not all palm oil companies can do.

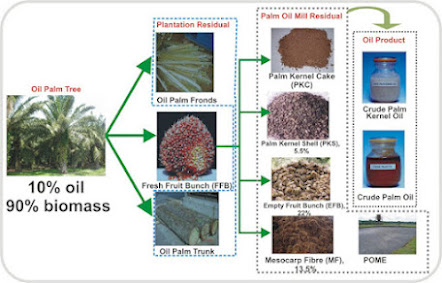

Biochar to improve soil fertility, increase fertilization efficiency so as to increase FFB productivity is the best solution. With the increase in FFB productivity, CPO production will automatically increase so that efforts to extensification through deforestation can be avoided. In fact, in addition to global CPO prices which can drop at any time, fertilizer prices can also increase at any time. This further encourages the biochar application efforts. The use of biochar in palm oil plantations is also a climate effort for carbon sequestration (carbon sink) or a negative carbon scenario to reduce CO2 concentrations in the atmosphere, so that this can generate additional income in the form of carbon credits, which have a higher value. Another factor is that in the palm oil industry or CPO production, only 10% of vegetable oil produced and 90% are biomass, while this amount of biomass has great potential as a raw material for biochar production.

And because organizationally the palm oil company is divided into a plantation division and a CPO mill division, so to facilitate operation the biochar production can be a separate business unit but still within the same company or it could be with another party. And for example empty fruit bunches (EFB) as raw material for biochar whose position is in the mill while the application of the biochar is in the plantation land. In addition to the benefits mentioned above, the production of biochar is also an effort to deal with biomass waste and produce energy that can be used for the production of CPO or in the mill. And when the CPO price drops but the production costs are low because the use of fertilizer in the plantations can be suppressed but the FFB productivity remains high, the losses experienced are also less.

Great Post!!

ReplyDeleteThanks for sharing this wonderful post with us. This post is more useful and helpful for find the best and unique quality of biomass wood pellets mills. Also, these mills easily produces wood pellets in any sizes and shapes.