The sun is the source of energy for all living things on Earth. It is an abundant, free, and inexhaustible source of energy, except at the end of the world. The word "sun" is mentioned 25 times in the Quran and is one of the chapters mentioned by Allah in the Quran. This indicates that Allah wants to signal that there is something that humans need to explore through the sun or asy-syams. Utilizing the sun for electricity production has attracted the attention and focus of scientists worldwide. And Muslim scientists, in particular, with this divine motivation from the Quran, should be motivated and driven to research and implement it. This driving force is especially strong in the era of decarbonization, or the substitution of fossil fuels for renewable energy to address climate change and global warming.

Ibrahim Abdul Matin (2012), a Muslim from the United States (US) and environmental activist, in his book Green Deen: What Islam Teaches about Protecting the Planet, refers to renewable energy as energy from heaven. According to him, energy from heaven comes from above, meaning it is not extracted from the earth and is renewable. "Extraction causes imbalance (causes climate change), while energy from above is like energy from heaven."

In practice, solar energy has been widely utilized to generate electricity. Humanity is challenged to develop the best science and technology to maximize the harvest and utilization of solar energy. Technology and supporting infrastructure have even been widely used as a powerful weapon to address climate change and global warming. However, in practice, not all implementations of this technology have been successful and yield significant financial returns. The Ivanpah project in California, USA, is one such project. The electricity production project, utilizing solar heat with CSP (Concentrated Solar Plant) technology, failed to achieve its business objectives and lost out to the more accessible and affordable solar PV (photovoltaic) technology.

CSP technology, or solar thermal technology, uses mirrors to concentrate sunlight, generating heat to produce steam to drive turbines, generating electricity. Meanwhile, in solar PV, the solar panels will directly absorb sunlight using semiconductor materials. The Ivanpah project, which cost 2.2 billion USD (more than 35 trillion rupiah), became a bitter pill for the development of solar energy utilization technology. The Pacific Gas & Electric (PG&E) company, as the main buyer, even terminated its long-term contract (PPA / Power Purchase Agreement) for purchasing electricity from the previous 14-year agreement from the Ivanpah project, forcing 2 of its 3 units to shut down. This was because the Ivanpah project with CSP technology was unable to produce adequate performance or performance, even for its operations still with additional natural gas.

For solar PV power generation, China is currently the world's leader or largest producer of solar power. China's ambition is to build a "solar great wall" designed to meet Beijing's energy needs. The multi-year project, estimated to be completed in 2030, will be 400 kilometers (250 miles) long, 5 kilometers (3 miles) wide, and reach a maximum generating capacity of 100 gigawatts. Currently, the project is reported to have reached a capacity of 5.4 gigawatts. Since 2024, China has led the world in electricity production from solar panels. As of June 2024, China led the world in operating solar power generation capacity with 386,875 megawatts, representing about 51 percent of the global total, according to Global Energy Monitor's Global Solar Power Tracker. The United States ranked second with 79,364 megawatts (11 percent), followed by India with 53,114 megawatts (7 percent).

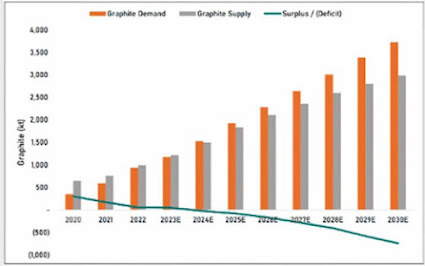

In the coming decades, large-capacity batteries, up to several MW, are predicted to be widely used in solar PV power plants. These batteries will enable solar PV power plants to continue supplying electricity at night or on cloudy days. Research and development of these batteries is ongoing, and it would be preferable if some of the battery components were derived from renewable sources, such as electrodes made from biographite (which is made from biochar), rather than synthetic graphite derived from fossil fuels, which are currently dominated by China.

Climate and weather factors significantly influence the operation of solar PV power plants. When weather conditions, such as cloudy days without sunlight, occur, electricity production is hampered or intermittent. Furthermore, the use of large-capacity batteries is not yet available and requires considerable time. This is why renewable energy sources that are ready at any time and are not affected by the weather are highly needed. Biomass energy sources such as wood pellets are one such energy source. Renewable energy sources derived from plants (bio-energy) are also in line with QS. Yaasin (36): 80. To produce these energy sources, whether from wood, fruit, seeds, or other parts of the plant, plants carry out photosynthesis. In addition to water and carbon dioxide (CO2), this photosynthesis process requires sunlight. The sun is very important as an energy source for living things, especially for plants. Renewable energy sources from biomass (bio-energy) are like "green batteries" that have great potential as a means of capturing solar energy, and for more details, please read here.