Bioeconomy is defined as knowledge-based production and uses biological resources or living things to produce products, processes, and services in the economic sector within the framework of a sustainable economic system.

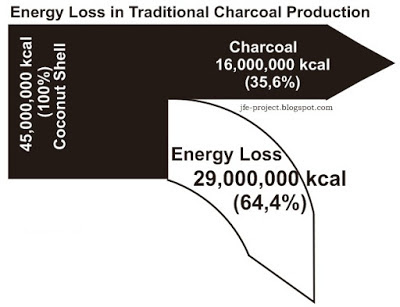

Almost all traditional charcoal producers have wasted a lot of energy in the carbonization process. Why is that ? Is not energy really needed in almost all industries, even in a number of industries, energy is the highest cost component? Besides being inefficient, isn't that the same as wasting money in vain? That is because in the production of charcoal with a conversion of around 25%, more than half is wasted. As an illustration like the following count. For example, we take a 25% conversion, with 10 tons of coconut shell raw material, 2.5 tons of charcoal is produced. Coconut shell with a calorific value of around 4,500 kcal / kg, means that 10 tons of raw material amounts to 45,000,000 kcal. Whereas coconut shell charcoal with a heating value of around 8,000 kcal / kg, then 2.5 tons of charcoal will have a heating value of 20,000,000 kcal / kg. Based on these calculations more than 50% of energy is lost or only wasted, which is 25,000,000 kcal. If the conversion to charcoal is lower or 20% then the energy loss is even greater, namely 29,000,000 kcal or more than 60%. Of course it is very inefficient.

The use of coconut shell charcoal that can be as direct fuel, or further processed into briquettes or activated charcoal. Besides being used in domestic or local markets, coconut shell charcoal is also an export commodity. Noted the export value of Indonesian coconut shell charcoal reaches 250 thousand tons / year, while by making briquettes and activated charcoal, greater value added will be obtained. Coconut shell charcoal briquette exports reach around 20 thousand tons / year while active charcoal is still relatively low at 25 thousand tons / year while providing the highest added value. Whereas white copra is the raw material for making coconut oil and for the main export destinations are India and Bangladesh. During its heyday, Indonesia was once the largest copra exporter in the world. As the use of coconut oil decreases, copra exports also decline. The world's white copra exports were 137 thousand tons in 2013 (APCC-Coconut Statistical Yearbook, 2013) with a total value of more than 2 trillion rupiah. Whereas nata de coco in general makes packaged drinks and many products can be found in various shops to supermarkets. The needs of nata de coco tend to increase with the population or more specifically in line with the growth of the food and beverage industry which reaches above 8% every year. It is estimated that business value for national nata de coco can reach 1.6 trillion rupiah, if managed properly.

|

| Integrated Coconut Industry Diagram |

Nice Post

ReplyDeleteWe are the Good HandiCraft Exporter in India. Here are some of my products. Please check it.

Eco-friendly jute product exporter in United Kingdom

Top handicraft exporters in india

Cane handicraft items exporter germany