The decarbonization trend continues in all sectors, especially in strategic industries such as the energy industry, iron and steel industry, and transportation equipment industry. The contribution of a number of these industries in producing CO2 emissions that increase concentrations in the atmosphere (carbon positive) is very significant, namely the energy industry, especially power plants, contributing 27.45%, the steel industry contributing 8%, and the transportation sector industry 24%. Various efforts have been made to reduce CO2 emissions from these fossil sources. Biographite is one of the important components for this purpose. The use of graphite currently comes from fossil sources, namely petcoke and coal tar, which are synthetic graphite. This is because graphite mined in nature cannot meet the expected technical specifications in the form of strength, density and conductivity.

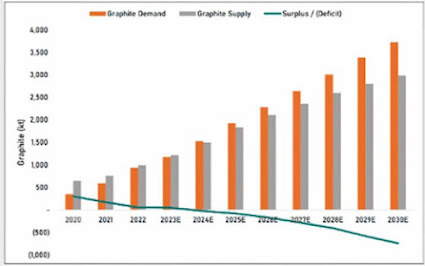

Graphite is a material that is used for steel making, lithium ion batteries, nuclear power plants, fuel cells and the defense industry. In the steel industry, every ton of steel produced with EAF uses 2-4 kg of graphite electrodes. On average, each electric car battery contains 70 kg of graphite. According to the Economist, in 2030, the demand for graphite is expected to exceed supply by 1.2 million metric tons, threatening the steel and battery industries. Meanwhile, according to the IEA for Europe, the need for graphite is predicted to increase by around 20-25 times from 2020 to 2040. Including why currently there is no very large battery capacity so that even coal-fired power plants or from fossil sources can be eliminated, it is very possible because of this graphite problem. In addition to graphite, nickel is an important component in lithium-ion batteries used in electric cars with an average of 30 kg, especially in the cathode. Nickel helps increase the energy density and storage capacity of batteries, allowing electric cars to have a longer range.

In the steel industry, carbon neutral production conditions will be achieved when iron and steel production in the industry uses 100% renewable energy. The use of electric furnaces (EAF / Electric Arc Furnace) can be done as long as the electricity is generated from renewable energy sources. And the fact is that currently to achieve this goal is still far because the construction of blast furnaces - basic oxygen furnaces (BF -BOF) is still widely carried out, which should be EAF (Electric Arc Furnace) or currently only around 30% of the global iron and steel industry uses this EAF. Even the International Energy Association (IEA / International Energy Association) highlighted this critical issue to achieve the Paris Agreement's net-zero target by 2050. With an average blast furnace life of 20 years, the iron and steel industry's efforts to achieve the target must be formulated and programmed properly. Even if the blast furnace replacement effort does not follow the target time, it will put the achievement of net zero emissions 2050 in danger. This makes the use of renewable energy as an energy source for EAF increasingly important and must be accelerated, which should also be in line with the use of bio-graphite in the EAF.

The use of biographite will reduce CO2 emissions and reduce dependence on imports. Bio-graphite which is basically derived from biomass offers a sustainable alternative solution to graphite derived from fossil materials. When applied in steel mills with EAF, although biographite emits CO2 emissions when used, this CO2 or carbon comes from biomass. And the biomass from the plant absorbs CO2 from the atmosphere when it grows, making the process carbon neutral. The bio-graphite production process begins by converting biomass into biochar. Furthermore, with special purification, the biochar is converted into high-purity graphite which is suitable for electric arc furnace (EAF) steel electrodes and battery anodes.

Source: Macquarie Research (March 2023)

Graphite demand / supply showing market deficit beginning 2025E

With the potential for various applications in a number of strategic industries, bio-graphite is not just a new environmentally friendly material but an important material supporting future industries. The shortage of this material could slow the transition to electric vehicles and renewable energy storage, which has an impact on many industries. And specifically in the steel industry, the shortage of this material will threaten to increase the cost of steelmaking and hinder progress towards climate goals. This is why the development of biochar production for biographite is very important and needs to be accelerated for the growth of various green industries or renewable industries in the future.

No comments:

Post a Comment