The decarbonization trend continues across all sectors, particularly strategic industries such as the energy industry, iron and steel industry, and transportation. These industries contribute significantly to CO2 emissions, which increase atmospheric concentrations (carbon positive). The energy industry, particularly power generation, contributes 27.45%, the steel industry 8%, and the transportation sector 24%. With an estimated total CO2 emissions from fossil fuels of 36.3 gigatonnes (36.3 billion metric tons) in 2024, the iron and steel industry's contribution is approximately 2.9 gigatonnes (2.9 billion metric tons).

In the steel industry, carbon neutral production will be achieved when iron and steel production in the industry uses 100% renewable energy. The use of electric arc furnaces (EAFs) can be done as long as the electricity is generated from renewable energy sources. However, the use of EAFs that still use electricity from fossil fuels can be a transition medium before 100% carbon neutral production because of its lower CO2 emissions compared to blast furnaces that use coke from coal. CO2 emissions from blast furnaces are around 2.33 tons for each ton of crude iron / pig iron, while with EAFs, they are only around 0.66 tons for each ton of crude steel. The raw material processed with EAFs is steel scrap, and approximately 80% of steel scrap is currently recycled with EAFs. Globally, steel production with EAFs reaches approximately 22%.

And the fact is that currently, to achieve this goal is still far because the construction of blast furnaces - basic oxygen furnaces (BF -BOF) is still being carried out a lot, which should be EAF (Electric Arc Furnace) or currently only about 30% of the global iron and steel industry uses this EAF. The construction of new blast furnaces is indeed tending to increase, in fact, by mid-2024, around 207 million tons per year of new production has been announced and around 100 million tons per year is under construction.

Nearly all CO2 emissions in the steel production sector come from blast furnaces (BF) for refining iron ore into crude iron or pig iron. The challenge is enormous: there are approximately 1,850 steel mills worldwide, with approximately 1,000 using blast furnaces, with pig iron production reaching approximately 1.5 billion tons per year. The International Energy Association (IEA) has even highlighted this critical issue in achieving the Paris Agreement's net-zero target by 2050. With an average blast furnace lifespan of 20 years, the iron and steel industry's efforts to achieve this target must be well-formulated and programmed. Failure to replace blast furnaces within the specified timeframe will jeopardize the 2050 net-zero emissions target.

This makes the use of charcoal to replace coal-based coke in blast furnaces crucial. Charcoal derived from biomass is a renewable, sustainable material used as a reducing agent or fuel in blast furnaces. The chemical reaction separates oxygen atoms from iron atoms, releasing CO2. This converts iron ore (Fe2O3) into crude (pig) iron. The difference is that because the carbon source as a reducing agent or fuel in blast furnaces comes from renewable and sustainable sources, this process is carbon neutral. Using coke from coal, which comes from fossil fuels, is carbon positive. Similarly, using natural gas as a reducing agent or fuel in blast furnaces, despite its lower carbon intensity, is still carbon positive.

However, if hydrogen from renewable energy sources (green hydrogen) is used as a reductant in the blast furnace, it will not produce carbon emissions but will produce water vapor (H2O), thus it is also a carbon neutral process. However, this will still take a long time, predicted to take several decades to implement. To produce a carbon negative process, the iron and steel mills that are already operating carbon neutrally must be equipped with CCS (Carbon Capture and Storage) devices, which will certainly be the next step. Furthermore, the use of renewable energy as an EAF energy source is also becoming increasingly important and must be accelerated, which should also be in line with the use of bio-graphite in the EAF.

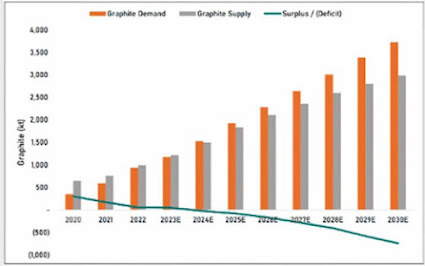

The use of EAF in iron and steel mills is estimated to reach 550 units worldwide with steel production reaching around 548 million tons or around 30% of the world's steel production which will reach around 1.8 billion tons in 2024. The use of EAF requires graphite electrodes and every ton of steel produced requires an average of 3 kg of graphite. The current source of graphite is almost all derived from fossil sources so it is a source of carbon emissions (carbon positive) and also currently around 80% of the world's graphite supply comes from China. With steel production from EAF of 548 million tons, the annual graphite demand reaches more than 1.6 million tons. Every ton of graphite production from fossil materials emits CO2 emissions of 17-40 tons.

This makes the use of biographite crucial because it is carbon-neutral, producing CO2 emissions. Biographite is produced from biochar, or charcoal, which undergoes a special purification process. The biochar is converted into high-purity graphite suitable for EAF electrodes. Biographite is used for its strength, density, and conductivity, not only because of the CO2 emissions mentioned above, but also because of its technical advantages. Naturally mined graphite cannot meet these technical specifications, while synthetic graphite from fossil fuels is not environmentally friendly and is highly dependent on imports. This is the driving force behind biographite production.

The demand for biochar or charcoal as a reducing agent in BF will be very large, while for biographite as an EAF electrode is not as large as in BF. This makes it crucial to obtain a source of biomass raw materials as a source of biochar or charcoal in sufficient volume, good quality, and sustainable. Similarly, in terms of biochar or charcoal production, which primarily uses pyrolysis/carbonization technology, it must also be able to produce products with adequate quality and quantity, sustainably, and with a production process that is high in productivity, efficient, and environmentally friendly. Biochar or charcoal with specifications of at least 85% fixed carbon and a minimum conversion (gravimetric yield) of 30% is the reference for selecting this pyrolysis technology.

In addition to biomass waste groups such as forestry waste and plantation waste, energy plantations can also be specifically created for this purpose, for more details read here. These energy plantations must also be created according to the land allocation and area of monoculture energy plantations in accordance with proper planning and procedures, as well as efficient and environmentally friendly pyrolysis / carbonization technology. Biomass sources as raw materials for charcoal / biochar can also be said to be sustainable if the harvested product is less or at most equal to the growth of the plantation's wood. This is to prevent what happened in Brazil, namely in the state of Minas Gerais. Due to the large area of monoculture eucalyptus plantations whose wood products are mostly for charcoal production for iron and steel mills, this has caused various negative impacts on the environment. Brazil is the world's largest charcoal producer and produced 5.2 million tons in 2017, 90% of which was used by the iron and steel industry, with 80% of the charcoal produced from eucalyptus plantation wood.

Approximately 70% of Brazil's iron and steel production occurs in the state of Minas Gerais, and this sector is unique in that 34% of iron production uses charcoal, not mineral coke/coal, and coke is also widely used in steel production. Historically, this was due to a lack of mineral coke in Brazil, but abundant forests for coke production. Minas Gerais currently has nine steel mills and 41 iron plants producing 3.1 million tons of crude iron in 2018, approximately 50% of which was exported. In 2018, Brazil had 5.7 million hectares of eucalyptus plantations, and Minas Gerais continues to have the largest plantation area in the country, covering 24% (1.4 million hectares) of Brazil's eucalyptus. Iron and steel companies also have eucalyptus plantations in an effort to secure a supply of charcoak for their iron and steel mills. Indonesia also has vast land potential, reaching hundreds of millions of hectares for these energy plantations.