The use of fossil fuels makes the transportation sector contribute 24% of global CO2. With CO2 emissions from fossil fuel use estimated to reach 36.3 gigatonnes (36.3 billion metric tons) in 2024, the transportation sector contributes 8.71 gigatonnes (8.71 billion tons) of CO2. Efforts to reduce CO2 emissions from the transportation sector are carried out in two ways: the use of renewable energy and the use of electric vehicles. The use of electric vehicles must be accompanied by the provision of renewable energy sources. Do not just use electric vehicles, but the energy source still comes from fossil fuel sources. Biofuel is a renewable energy source for the transportation sector that can be used directly with minimal vehicle modifications or even without any engine modifications at all. The question of whether to prioritize electric vehicles first or the use of biofuels first can be read in more detail here.

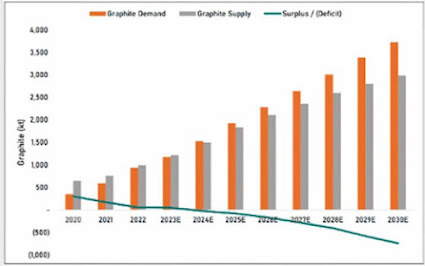

Electric vehicles can indeed be a decarbonization solution in the transportation sector, with the aforementioned considerations. And it would certainly be even better if the production of these electric vehicles also used materials from renewable sources, such as graphite for batteries derived from biochar or components such as chassis, body, and other metal components from "green steel" or "low carbon steel." Regarding graphite from biochar or biographite, with an average of 70 kg per car required, with projections according to the International Energy Agency (IEA) that electric car production by 2030 (including buses, vans, and heavy trucks) reaching 145 million units, the need for biographite will reach more than 10 million tons. In fact, according to the Economist, in that year, graphite demand is expected to exceed supply by 2 million metric tons, thus threatening the steel and battery industries. This means graphite production needs to be increased, but of course, that production will be biographite for better environment aspect, not synthetic graphite derived from fossil fuels. Meanwhile, in Indonesia itself, the government is targeting 2 million electric cars and 13 million electric two-wheeled vehicles by 2030. The use of biographite is intended to replace graphite derived from fossil sources which is still commonly used and with China as the main producer (controlling more than 80% of global (synthetic) graphite production).

Furthermore, Indonesia is rich in nickel, with reserves reaching approximately 5.3 billion tons of ore, equivalent to approximately 55 million metric tons of nickel metal (East Asia Forum, 2024), and holds the world's largest reserves. Australia ranks second with approximately 24 million metric tons of nickel metal, while global nickel reserves are estimated at approximately 130 million metric tons. This should place Indonesia in a strategic position in the era of electric vehicle use. In 2023, Indonesia produced approximately 1.8 million metric tons of nickel, accounting for nearly half of total global production (Statista, 2023). Nickel helps increase the energy density and storage capacity of batteries, enabling electric cars to have a longer range. Each electric car battery is estimated to use 30 kg of nickel. With the International Energy Agency (IEA) projecting electric car production by 2030 to reach 145 million units, the need for nickel will reach nearly 4.5 million tons.

In addition to properly managed nickel mining for environmental sustainability, the country's natural resources, particularly nickel, should also be processed into finished products domestically. Exporting semi-finished products or even raw materials, which offer little added value and are less profitable, should be avoided. Furthermore, if all nickel were exported to China, the world's largest graphite producer, it would make China a major global producer of electric car batteries. With biographite production, Indonesia would become less dependent on imports, and downstream nickel processing would make its own electric battery production highly feasible, potentially even becoming a major player in the battery industry. Nickel is also used in the production of stainless steel, a widely used material.