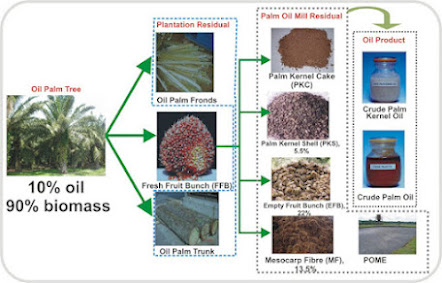

Even though biomass waste is abundant in the palm oil industry, both in the plantation area and in the palm oil mill area, most of the biomass waste, especially empty fruit bunches or EFB, is still not utilized or is simply piled up or thrown away. In fact, if the palm oil industry has a strong vision about maximizing profits by minimizing the occurrence of waste, especially biomass, and maximizing environmental sustainability as well as being part of the climate solution, then biomass waste, especially empty fruit bunches or EFB, is a big opportunity. Currently, special department in the palm oil industry that specifically deal with sustainability issues are starting to be created by palm oil companies. Waste management issues including the utilization of EFB, reducing soil and water pollution due to fertilizers and increasing fertilizer efficiency are the concerns of the sustainability department.

The empty fruit bunches or EFB can be used as fuel so that most or all of the palm kernel shells or PKS can be sold directly and even exported. Palm oil mill boiler fuel currently uses fuel in the form of palm fiber (mesocarp fiber) and some palm kernel shells / PKS, which can be replaced using empty fruit bunches (EFB) and palm fiber (mesocarp fiber) and without palm kernel shells / PKS. Palm kernel shells / PKS are a very popular biomass fuel in the global market that competes fiercely with wood pellets. By being able to sell all palm kernel shells / PKS and at the same time utilize empty fruit bunch / EFB waste, the palm oil industry will provide many economic benefits.

The use of empty fruit bunches / EFB and mesocarp fiber as a heat source for the boiler is not burned as usual or as is done by all palm oil mills today but must be gasified or pyrolyzed so that another product is produced in the form of biochar. Although gasification can be used to produce biochar, pyrolysis is more recommended because the quality and quantity of biochar will be better. The biochar can later be used for the palm oil plantation itself. The use of biochar in palm oil plantations will significantly save on fertilizer use as well as reducing water and soil pollution due to inefficient use of fertilizer. The biggest cost in operating a palm oil plantation is fertilizer, so by using biochar these operational costs can automatically be reduced. Biochar will become a slow release agent so that fertilizer use will be more efficient or increase NUE (Nutrients Use Efficiency).

Empty fruit bunches / EFB and mesocarp fiber are solid waste from palm oil mills so the waste is located around the palm oil mill, while biochar is used for palm oil plantations. In palm oil companies, management is generally separated between the plantation and mill departments. The use of biochar in palm oil plantations while the raw material comes from palm oil mills requires special arrangements regarding this matter. This could be, for example, trucks transporting fresh fruit bunch / FFB from the plantation to the palm oil mill, then after the FFB is unloaded at the mill, they then go to the plantation again carrying biochar from the palm oil mill.

Currently, no one is utilizing empty fruit bunches / EFB and palm mesocarp fiber as a source of boiler heat and biochar production. The main factor causing this is the main orientation or vision of the palm oil company itself as described above. This is predicted to change soon as awareness of climate issues increases and reaches all levels, especially in sectors related to energy and sustainibility. Moreover, when biochar is applied to plantation land, it also gets carbon credit as carbon sequestration. The smoke coming out of the boiler furnace will also be cleaner as seen from its opacity. The use of gas and liquid fuels from pyrolysis by-products will produce better combustion quality as well as smoke from the chimney. And even the liquid products from pyrolysis can also be used as biopesticides and organic fertilizers. Boiler efficiency will also increase because it uses boiler feed water (BFW) in the form of hot water from the condenser output of the pyrolysis unit.

Apart from old palm oil mills which really want to upgrade their industrial energy systems and fertilizer efficiency in their plantations including sustaibility according to this vision, new palm oil mills whose status is in the development stage should be able to apply this concept more easily. New palm oil mills can immediately follow developments and demands of the times so that they become trend setters with this vision. Being a pioneer and trend setter is indeed more difficult and even risky than just being a follower, but this will raise the reputation and become a leader in the industry so it should also have a positive impact on the company's business performance. A worthy effort.